Choose the Right Demolition Hammer for Your Project & Tips for Safe Operation

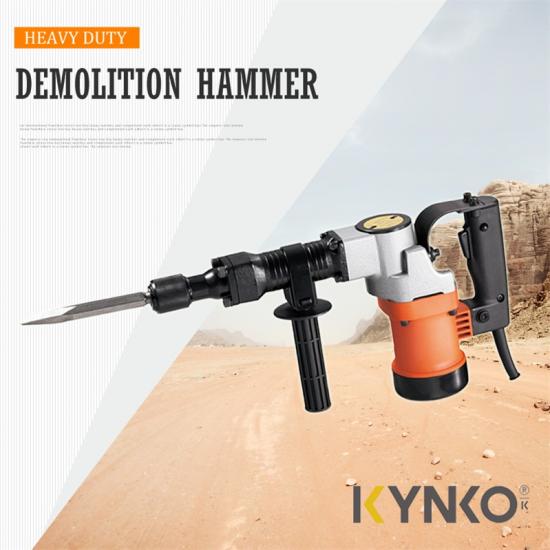

A demolition hammer, also known as an electric breaker, is a must-have tool for heavy-duty demolition work. Whether you're breaking up concrete, removing tiles, or doing chiseling work on walls and floors, choosing the right demolition hammer ensures efficiency and safety.

1. Working Principle of Demolition Hammers

Demolition hammers operate using an internal piston mechanism that delivers high-impact blows to a chisel or point bit. Unlike rotary hammers, demolition hammers do not rotate. They are specifically designed for breaking and demolition tasks rather than drilling.

These tools use either an electric or pneumatic motor to drive the hammering motion. The repeated impact force makes quick work of tough surfaces such as concrete, brick, masonry, and asphalt.

2. Applications of Demolition Hammers

Building Installation: Used for breaking through concrete or masonry to create space for new installations, such as piping, wiring, or other structural components.

Water Electricity – Water and Electrical Channeling: Essential for creating precise channels in walls and floors for water pipes and electrical wiring installation.

Demolition of Blasting Die: Employed in the removal of hardened blasting dies in industrial and mining applications.

Stone Mining: Used in the extraction of natural stone from quarries, aiding in the breakdown of large rocks and stones for further processing.

They are ideal for construction professionals, contractors, and serious DIYers who need to remove solid materials quickly and efficiently. Depending on the job size, you can choose between lightweight models for vertical wall work or heavy-duty versions for floor demolition.

3. Key Factors to Consider When Choosing a Demolition Hammer

01. Power and Impact Energy

Demolition hammers come in various power ratings, typically ranging from 1000W to over 2000W. The higher the wattage and impact energy (measured in Joules), the more powerful the tool. Remember: More power generally means a heavier tool. Choose based on task and operator endurance.

For small jobs like tile removal: 1000W–1200W models are sufficient.

For heavy concrete demolition: 1500W–2000W+ with high impact energy (30J–60J) is recommended.

02. Tool Size and Weight

The physical size and weight matter, especially if the work involves vertical surfaces or extended usage. For overhead or wall chiseling, a compact, lightweight hammer (5–8 kg) is preferred. For floor demolition, heavier models (10–18 kg) offer more impact and stability.

03. Comfort and Vibration Control

Look for ergonomic designs with: Anti-vibration handles; Soft grips; Balanced body weight distribution

Reduced vibration lowers user fatigue and improves control. Our KD83 Demolition Hammer, for example, offers excellent vibration damping with a powerful 1600W motor and 45J impact energy, making it ideal for prolonged work.

KYNKO New Demolition Hammer Models with Power Up to 1700W: KD56 & KD11

KYNKO 6kg Demolition Hammer KD23 : Compact and Lightweight for Easy Handling

4. Tips for Safe Use of Demolition Hammers

Demolition hammers are powerful tools, and improper handling can result in injury or equipment damage. Always follow safety procedures

01.Before Use:

Wear safety goggles, gloves, and dust masks.

Check the power cord and tool condition.

Choose the correct chisel bit for the material.

02.During Operation:

Hold the hammer firmly with both hands.

Keep the cord clear of the working area.

Let the tool do the work—don’t apply excessive force.

Avoid using the tool in wet or unstable conditions.

03.After Use:

Disconnect power before changing bits or storing.

Let the tool cool before packing it.

Clean dust from air vents and body.

5. Summary

A demolition hammer is essential for any serious demolition task. When choosing the right model, focus on power, impact energy, tool weight, and ergonomic features. Avoid selecting a tool based solely on wattage or price—overall quality and user comfort are just as critical.

By using demolition hammers properly and observing safety measures, you can complete tasks faster, more safely, and with better results. For professional-grade performance, always choose reliable manufacturers with strong after-sales support and a reputation for quality.

Categorias

último blog

Tag

© Copyright: 2003-2025 KYNKO INDUSTRIAL LIMITED Todos os direitos reservados.

IPv6 network supported

Talk by Wechat